Why Conveyor Belt Safety Switches are a necessity

The safety of a Conveyor Belt is very important. This is because a malfunction in a belt can cause a catastrophic accident at a place where heavy equipment is being moved. This is precisely why many industries are now requiring safe belt systems that have a high tolerance for wear and tear.

The safety of these belts should be of top-most importance since the lives of workers depend heavily on their ability to work safely. To ensure that Conveyor Belt Safety is maintained properly at all times, it is important for an operator to install the safest pull switch products in his or her workplace.

The size of these belts to transport the material to other areas is spread out over a number of kilometers, to control and oversee the smooth operation of the system. It is important to have operators who know how to operate and handle these types of belts to avoid any unwanted accident in the workplace.

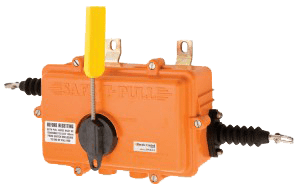

It is also necessary for such operators to be trained in the use of emergency stop and pull systems in place for emergency usage.

Most of these emergency stop and pull switches are used for emergency usage only where the Conveyor is affected by some sort of mechanical, environmental, electrical or optical issues. This means that it has a very limited lifespan and may need replacement in the near future.

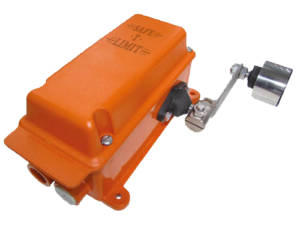

Safety of these belts is ensured by a number of features including smooth functioning, safe speed, and a safe operating environment. This is achieved through the installation of the safe t rip switches or belt drift switches.

An automatic tripping wire breaks the pull operation if a tripping wire is detected.

These Conveyor Safety Switches are available at Power Control Products.