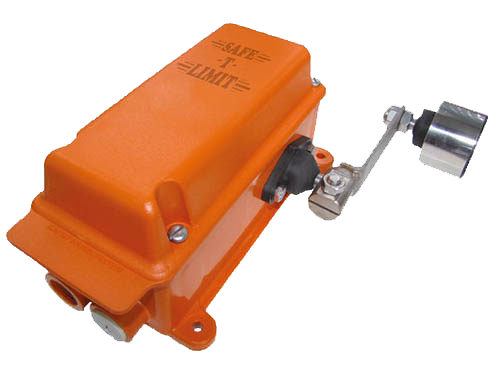

SAFE-T SEEKING SIL RATING

Independent SIL Rating Timeline

Undergoing comprehensive testing and ensuring compliance

TESTING OF ELECTRICAL COMPONENT

To prove compliance with IEC 60947-5-1, Electric Control Products designed a microswitch to meet the stringent specifications required to pass certification.

MECHANICAL CYCLE DURABILITY TEST

Together with SIMTARS, using our Automation Tester, we completed 6050 full-cycle tests on nine samples, in three materials over a three-week period.

ELECTRICAL DURABILITY TESTING

The next phase involves shock and vibration resistance, electrical integrity at 2,500 V, reset functionality, and operation after wire disengagement.

AUTO MECHANICAL DURABILITY TESTER

To prove our pull wire devices can handle 6050 cycles, we developed a custom Automation Tester, perfected over eight years, which accurately simulates real-life conditions, ensuring our products meet rigorous durability standards.

ENVIRONMENTAL DURABILITY TEST

The next phase is subjecting devices to extreme conditions, including high and low temperatures, humidity changes, and saltwater exposure over 96-hour tests, ensuring resilience in diverse environments.

Electric Control Products' Journey to SIL Certification through Rigorous, Independent Testing

Our devices are undergoing testing to meet the required standards for safety systems that demand a high level of reliability. These systems require a SIL rating, and the devices used in these systems must meet specific failure rate criteria as part of the overall SIL calculation.

To determine the failure rate, the device must undergo comprehensive testing to ensure compliance through a full Failure Modes and Effects Analysis (FMEA). Most devices on the market have not undergone actual testing but have been reviewed to state their compliance should they be subjected to testing. Electric Control Products made the deliberate choice to follow a comprehensive independent testing regime to attain full compliance. While it may be a lengthy process, the benefits will far surpass the time and effort invested. Obtaining SIL certification through real-life testing conducted by an independent certification authority will offer certainty and confidence in Electric Control Products’ devices among safety-driven industries.

BENEFIT OF FULLY INDEPENDENT TESTING

- Independent Verification.

- Engaging third-party testing facilities for device durability assessments and partnering with functional safety auditing companies to conduct a comprehensive device FMEA offers an impartial and unbiased evaluation of the device’s safety and performance.

- Certification Authority.

- Securing a well-documented durability safety test certification that can be relied upon and will be recognised by relevant certification authorities and regulatory bodies is crucial for trust in the testing process.

- Safety Integrity Level (SIL).

- SIL serves as a measure for assessing the performance of safety systems employed across diverse industries. Having a fully endorsed performance level applicable to any SIL calculation ensures that Electric Control Products’ devices are well-suited for a broad range of safety-critical applications.

- Real-Life Certification.

- The certification is not merely a letter of intent but a concrete, real-life documented safety test certification, offering tangible evidence of the devices’ safety and reliability.

- Industry Recognition.

- With the successful completion of rigorous independent testing, industries with stringent safety requirements, such as manufacturing, process control, and others, can have certainty and confidence in Electric Control Products’ pull wire devices meeting their specific requirements.

FAILURE MODE & EFFECTS ANALYSIS (FMEA)

The final, and most significant, milestone in the certification process involves the engagement of an independent functional safety auditing company. Their role is to conduct a comprehensive FMEA assessment and determine the SIL rating of Electric Control Products’ Safe-T-Pull pull wire devices. Once their assessment, review of documentation, and the completion of a rigorous testing regime confirm compliance with the applicable safety standards, they will issue certification.

This safety test documentation and certification offer invaluable assurance to our end-users as it signifies that our pull wire devices not only meet but exceed the high safety standards required for their critical applications. Furthermore, it serves as tangible evidence of Electric Control Products’ unwavering commitment to safety and quality assurance. This certification also adds substantial credibility to our claim that the company’s pull wire devices are meticulously designed and manufactured to the most rigorous industry standards, ensuring the utmost safety and reliability for our customers.